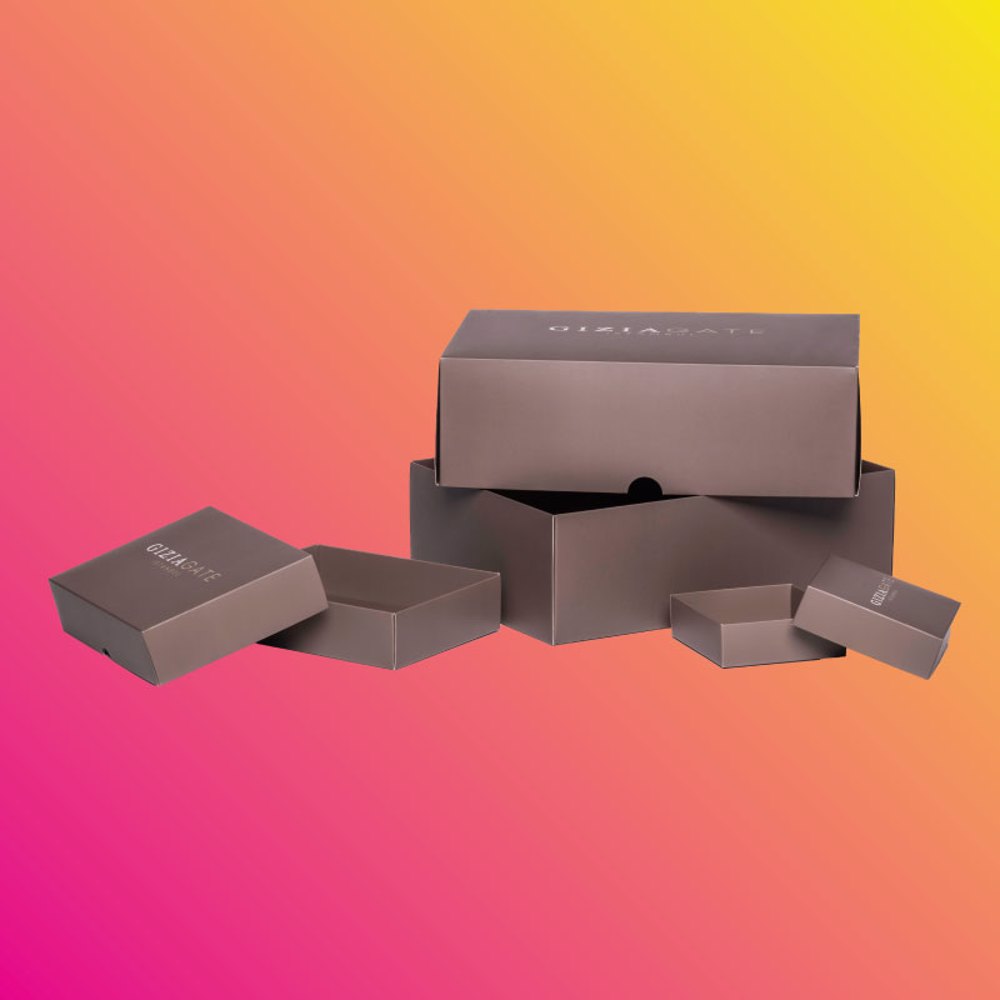

Wrap Around Box

Wrap-around boxes are preferred for packaging white goods, food, optical products, watches, consumer goods, creams, perfumes, cosmetics, technological devices, and other medium-weight products that require durability. Thickness and sturdiness are achieved by applying a wrapping process to the cardboard for wrap-around boxes. Once boxes are cut with a special knife, they undergo folding and gluing processes to attain their final look.

Wrap-around boxes stand out for their strength and are categorized as luxury boxes. They are produced by MKM Offset in different sizes, using materials such as kraft paper, American Bristol paper, first-grade paper, or chrome paper, depending on the type of product and the brand's preference.