Offset Process

The printing process begins after the submission of client's request that includes product information, graphic design and qualities of the printing.

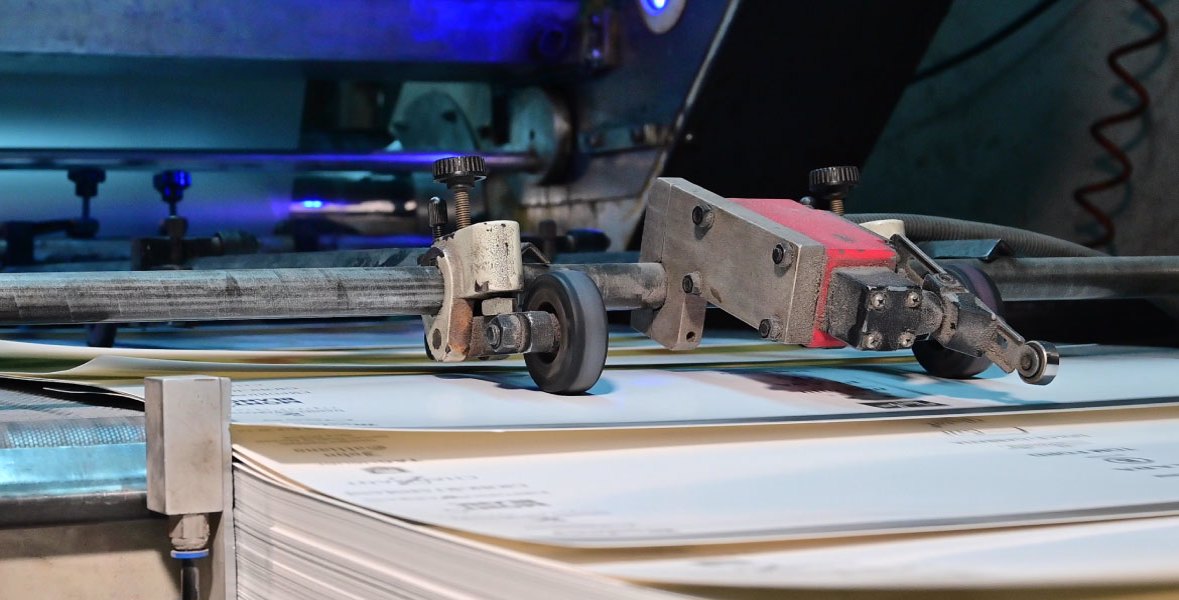

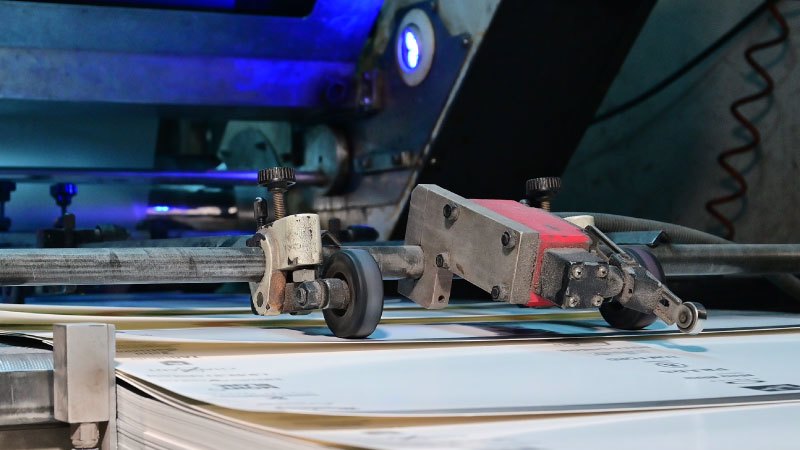

Offset

After being resized to the desired size, kraft, chrome, American bristol or premium pulp papers go through the printing process. The materials cut according to the number of the colors used in the printed graphic are sent to a 2-color or 4-color printing machine.

Samples are taken from the process to control the quality of the print.

Cellophane

Cellophane is optionally applied to the surface of carton bags and boxes to give the product a stylish look and to protect it. The surface of the treated material is covered with a thin, transparent film layer in Cold Double Lamination Machine. Upon request, matt cellophane giving the product a fuller appearance, glossy cellophane giving a more vivid appearance or mother-of-pearl cellophane can be applied.

Here, the rolled products are separated in the separator machine and prepared for the next stage.

Foil

After cellophane application, materials are subjected to a foiling process. As part of the process, sections such as logo, slogan to be highlighted in the graphic work are covered with gold, copper or silver foil. The foiling process applied with the Gilding Printing Machine, upon brand's request, gives products a stylish look.

Cutting-Embossing

During cutting process, samples are taken from the products, and the folds and joints of the products are controlled. The finished carton boxes are sent to the shipping point, and the carton bags are sent to the gluing process.

Guillotine

Carton boxes and bags whose processes are completed are trimmed and cut in the Printing Guillotine Machine.

Gumming

With the gluing process, carton bags are given their final shape. After the process, rope, ribbon are added and products are made ready for shipment.